Motor Terminology

Kv - RPM Constant The higher the voltage, the faster a motor spins. The Kv rating designates the RPM a motor will spin at full throttle when unloaded given an input voltage. To estimate the RPM of a motor, simply multiply the Kv value by the battery voltage. Kv is in units of RPM/Volt.

RPM= Kv * Voltage

Kt - Torque Constant The more torque a motor needs to produce, the more current it will draw. The Kt rating designates the amount of torque a motor will produce given a current. To estimate the torque of a motor, simply multiply the Kt value by current. Kt is in units of Inch*Ounce/Amp.

Torque = Kt * I However, usually you will need to find out how much current the motor will draw based on a torque. The equation then becomes

I = Torque / Kt

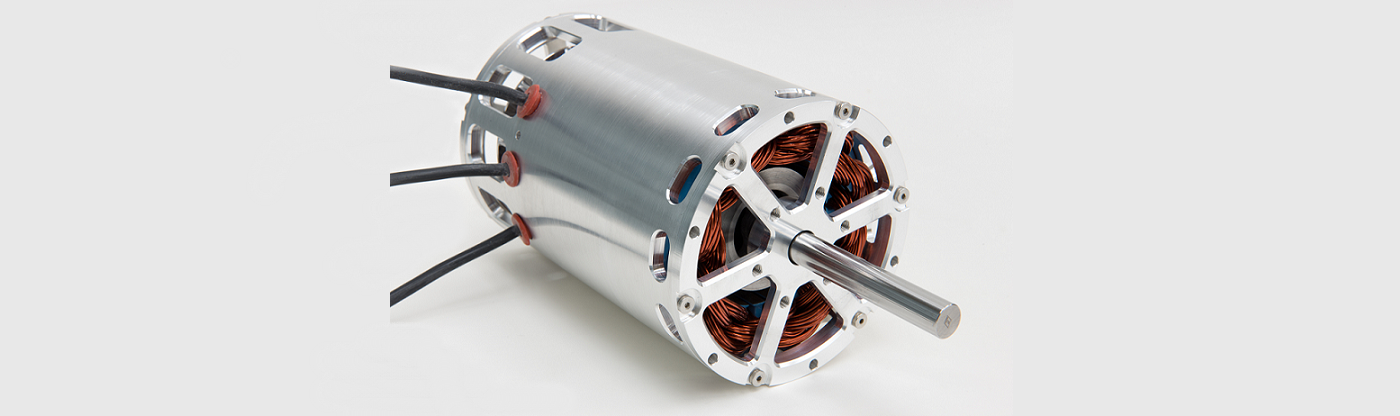

Rw - Winding Resistance Winding resistance has to do with the electrical resistance of the motor. In the case of 3-phase brushless motors such as the Astro Flight 32xx series, the motors have three wires coming out of the housing, one for each phase. The amount of electrical resistance across any two of these three phases is the winding resistance. This parameter is very important for calculating the efficiency of a motor. The less winding resistance, the better your efficiency will be. Rw is in units of Ohms.

Copper Loss There are two main ways for a motor to lose efficiency (losing efficiency means using battery power, but not contributing to the mechanical output). Copper loss is one of them. Copper loss refers to the heat generated when a wire conducts current. Copper loss is in units of Watts.

Copper Loss = I 2 * Rw

I0 - No Load Current I0 (pronounced "i-naught") current has to do with the amount of current needed to run the motor when there is no load attached. Even if a motor is not powering anything, it still requires a small amount of current just to spin. I0 is in units of Amps.

Iron Loss Iron loss is the other main way a motor loses efficiency. Iron loss has to do with the power lost due to fluctuating magnetic fields in the motor and is directly related to I0 and the voltage applied to the motor. Iron loss is in units of Watts.

Iron Loss = V * I0

Efficiency The efficiency of a motor is very important for a variety of reasons. First, motors with higher efficiency will be able to run longer on a given battery. Second, higher efficiency motors don't produce as much heat. This allows them to be pushed harder to deliver more power in continuous and burst applications. This also allows the designer to use a smaller and lighter motor. • Efficiency equals the amount of output power divided by the input power… • Efficiency = (Power Out) / (Power In) • Power Out is equal to the power that is left over after you subtract the copper and iron losses… • Efficiency = (Power In - Copper Loss - Iron Loss) / (Power In) • Finally, we can substitute our motor parameters into the equation to get…

Efficiency = ( V*I - I 2*Rw - V*I0 ) / ( V*I) This is a very basic equation that can be used to get a rough estimate of the efficiency. There are more complex equations that will yield more accurate results. But this will give you a rough approximation of the efficiency given Input Voltage (V), Input Current (I), Winding Resistance (Rw), and No Load Current (I0). Efficiency is unitless.

Turn Count The more turns a motor has, the slower it will spin. Turn count is how many times the wire is wound around the tooth of a stator. It is inversely proportional to the Kv of the motor. For instance, a 3210 4T has a Kv of 339 RPM/V. From this, it can be determined that the Kv of a 3210 8T is 165 RPM/V (339 RPM/V * 4T / 8T = 165 RPM/V). Further, the turn count is also directly proportional to the Kt of the motor. Using the same example, a 3210 4T has a Kt of 4 Inch*Ounce/Amp, which means the 3210 8T has a Kt of 8 Inch*Ounce/Amp. There is an common misconception that increasing the turn count is the same as gearing down. It is true that by doubling the turn count while maintaining the same input voltage and current yields half the RPM and double the torque, which is the same result as using a 2:1 gear ratio. However, spinning the motor at half the RPM will also half the maximum output power of the motor. This is because the maximum torque of all motors of a specific motor size (eg. 3210) is the same and unaffected by turn count (the reason they're all the same is because there is the same amount of copper loss). For example, the 3210 4T has a Kv of 339 RPM/V. We have a 50V power supply to use and would expect to get about 17,000 RPM (339 x 50 = 16,950). However, 17,000 RPM is too fast for our application. We want to run our at half that speed, 8,500 RPM. To achieve this, we have 3 options: we can use a power supply of half the voltage (25V), we can apply a 2:1 gear reduction, or we can use a 3210 8T. We opt for the 3210 8T to avoid having to buy a new power supply and to avoid having to add a reduction system, but after looking at the application specs, we realize that we need 500 Inch*Ounce of torque for the product to work correctly. The 3210 series, however, can only supply 375 Inch*Ounces (any more and the excessive copper loss would cause the motor to overheat). The only option that will fit our needs is to use a 2:1 reduction on the 3210 4T. By doing so, we've achieved our desired RPM and also can afford a bit of overhead in torque (the reduction allows us to have a maximum torque of 750 Inch*Ounces).

The following are the specs you will need in order to choose the correct motor for your application: 1. RPM you want the motor to spin at when at full throttle 2. Maximum torque you expect your load to pull (and at what throttle) 3. Battery voltage and current capabilities 4. Size and mounting limitations

|

||

More InfoYour Shopping Cart |